AKIS II-GRD Build Guide

- josephaguilarsanch

- Mar 14, 2024

- 7 min read

A formerly classified helmet for stalkers, killers and assassins, refitted for Spartan use.

Full description and file set available on the main product page.

The AKIS helmet comes with a suite of 5 attachments, full ventilation and audio integration, and my unique multi-part design that allows for a quick and easy assembly process

This Build Guide will list the following:

Require materials to complete the project

Assembly videos to walk you through the assembly process

Recommendations for Print Settings/Orientations for certain pieces

Any additional questions you have concerning the building of this model can be sent directly to me via the contact page on my website

Build Requirements

Visor Requirements (Basic)

Visor Requirements (If Vacuum Forming)

Electronics

40mm Hobby Fans (For the Side Vents)

2x 36 mm Speakers (Hobby speakers that can be powered/connected to the Bluetooth Reciever via a 3.5 mm jack)

Bluetooth Reciever w/ headphone jack (Allows helmet to connect to your phone/computer)

Misc:

TPU: can be used to print out the tubes on the side of the gas mask. If you don't want to print the hose, any 2 inch diameter (52mm) hose will work

M3 Bolts: Can be used to secure the Left Lense to the Top and Bottom Lense Clips if you dont want to use the included, printable Lense Bolts

Assembly Instructions:

This tutorial is broken into 4 separate parts

Helmet Assembly

- This will showcase how to assemble the base helmet and attach all types of attachments

Electronics Assembly

- This will showcase how to integrate all the optional electronics

Ventilation Assembly

- This will showcase how to integrate all the optional electronics

Visor Fabrication

- This will feature a full write up for vacuum forming and tinting your own visor

Helmet Assembly

The video below contains written text to illustrate how to put together the base helmet bucket.

Start with the Face Mask, Lower Bucket and the Gas Mask. There are 3 oval shaped pegs that will secure these three pieces to each other to comprise the entire lower assembly. If you printed the hoses or are using external tubing, those can be inserted at this point

You can now place the Top Bucket over the top lips on the Face Plate and the Lower Bucket to form the main body of the helmet.

The Top Bucket, Lower Bucket and Face Mask can all be secured to each other by inserting the Side Caps into their three associated alignment keys. You can also insert the attachment ports. There is a closed version and an open version that fits the attachment rod which is what all the side attachments mount upon.

Now we can place all the accents needed for the rear external cable/strap assembly. Place the Rear Cable Insert and Rear Cable Loop into their associated slots in the Lower Bucket. There should now be a channel leading from the Side Cap, through the Loop, Insert, and then back into the helmet through which you can snake through wires, or straps depending on how you want the helmet to look. To most closely match the ingame design, some sort of strap or woven cable cover would look most accurate.

Now we can attach the front accent pieces. Attach the Latch Accents to the sides of the Face Mask and the Septum to the top of the Gas Mask.

At this point, pop your right lense into the Right Eye and screw it into the Face mask

Secure the Left Lense to the Top Lense Clip and Bottom Lense Clip via the Lense Bolts. Alternatively you can use two M3 Bolts. Insert the Top and Bottom Clip into the slots in the Face Mask

Lastly, you can screw the Gas Filter into the Gas Mask

You are complete with the base helmet! Time to move on to the attachments!

Electronics Assembly

Below I will highlight all the compartments and accomodations for the various peripheral devices that can be added to the helmet. All parts can be fastened with hot glue or doublesided adhesive tapes, velcro, etc.

Starting off, there is a large compartment in the Top Bucket that can be used for a AA battery bank or general storage

There are external strap/cable guides that appear in-helmet that can be used to snake straps/cables from the speaker cavity to the rear of the helmet.

The speaker fits inside a cavity inside the side cap. If you only want to use speakers, the speakers themselves dont require external power. You can lead them straight to a bluetooth reciever which can be stored in the large rear compartment, or two a 3.5 mm jack.

These side compartments houses the side fans and features a large cavity that leads to the front and rear vents. The fans themselves sit on a small mounting lip that can be used to adhere the fan to the side ducts.

Ventilation Assembly

In addition to the ducts/fans mentioned in the electronics assembly there are a number of additional airflow ducts and air intakes in the base helmet.

Below you can see that the Gas Mask has an open front grill to allow for increased airflow into the helmet and to lessen the muffling affect of your voice. There is a large cavity in the gas mask if you also want to include a large fan in the front of the helmet.

The Gas Mask comes with an open and closed variant. Additionally there are side tubes leading into the gas mask and connect it to the side of the helmet.

Lastly there is a side gas filter which features 8 external air intakes into a central core duct leading into the Gas Mask.

Vacuum Formed Visor

The files include a 3D Printable Buck to allow those with experience in vacuum forming to produce 100% accurate visors. I will create a separate build guide in the near-future for those not experienced in vacuum forming.

General Printing Tips

I have a few printing tips to give on certain pieces to ensure that you get the best print quality. These are just recommendation and are by no means the only way that these parts can be printed.

The first pieces to print of this helmet should be the sizing ring. It can be printed flat and only takes 1-2 hours. In the long run this will likely save you hours if not days of printing when you can be sure that you will print the helmet at the correct scale the first time around. Keep scaling the rings up or down till you find your ideal fit and then scale the rest of the helmet to that scale. While there is a demo model that can be used for things like armor smith, this will ensure that the opening of the helmet can fit over your head. The "neck" of the sizing ring assembly is equal in shape and size to the opening of the helmet.

The helmet was designed to be a simple slip-on helmet, so if the sizing ring fits over your head, so will the helmet.

The pieces are not pre-oriented so you will have to adjust them to ensure they are in an orientation more optimally for printing (flat surfaces touching the build plate). Additionally, for pieces that have no ideal flat surface, I highly recommend using the Cylindric Custom Support downloadable plug-in for the Ultimaker Cura Slicer. It allows you to place custom supports on parts to ensure that you can get much safer and reliable prints on parts with odd geometries. Some of the examples below will show these custom supports, you will need to add them, or something similar to your own prints.

Optimal Print Orientation

Load Bearing Pegs/Screws/Rods

All Pegs should be printed as shown, this will ensure the layers aligned with their longitudinal axis and prevent Pegs shearing apart in the helmet.

The following pieces would benefit form this orientation

Peg x3

Lense Bolt x2

General Piece Orientation

The largest piece is the Top Bucket and has a couple possible orientations. While the front face is flat and can be pressed directly onto the build plate, this will leave a large overhang on the top of the print (see right picture). Using custom supports you can angle the helmet until that overhang no longer exists. Then place supports along the bottom of the print as well as some stabilizing supports along the spine of the helmet to ensure it has a nice wide base and wont fall over during the printing process.

The Face Mask's top face is flat and will ensure that the faces on its bottom side will be more precise and easy to fit into the Gas Mask and Lower Bucket

The Lower bucket will need to be angled forward to fit inside the print volume. Once this is done, I recommend placing an entire ridge of supports on the underside of this print including under the bottom-most edge of the side ducts.

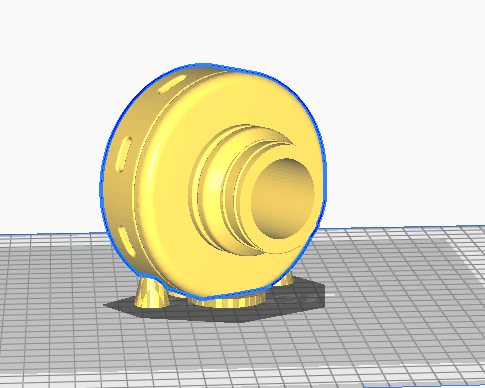

The gas filter has a flat face on its bottom and top face but this will likely lead to lots of internal supports which are difficult to remove and potentially some lost detail. You can print it on its side with some custom supports to reduce the aforementioned issues.

The Gas Mask has a couple of flat faces that can be used to easily adhere it to the build plate. Both orientations will come with their own share of potential issues (high number of supports/support faces in highly visible areas.) but are viable. One additional option is to angle the gas mask as shown in the right-most picture. This will require custom supports on the bottom but will reduce the overall amount of supports and prevent any of those supports from touching the front grill. This will require some amount of bridging from your printer for the front grill.

Various pieces have flat faces built in for ease of printing, those are listed below

Top and Bottom Lense Clip

Right Eye

Side Caps

Attachment Ports (open & closed)